BERKELEY, CA, USA, Apr 1, 2024 — Solideon, a US-based provider of collaborative robotic metal 3D printing systems and LEAP 71, a Dubai-based developer of computational and AI-based engineering technology, signed a strategic agreement to collaborate on the design and production of multi-meter-scale hardware for space applications.

The two companies will work together to build metal structures of significant scale with the eventual goal of enabling off-planet production.

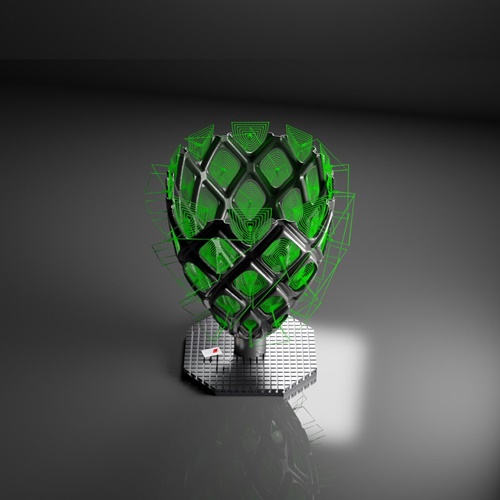

LEAP 71 and Solideon have been collaborating for the past year to interface between LEAP 71’s proprietary Computational Engineering Models (CEM), which are generative frameworks for building sophisticated physical objects, and Solideon’s large-size collaborative robotic metal manufacturing technology, Aperture.

Josefine Lissner, Founder and CEO of LEAP 71 said: “Access to space will expand significantly in the coming years. But how do we build the large components that will be needed to create extraterrestrial infrastructure? LEAP 71’s computational models can design sophisticated space hardware, however, limitations of the current manufacturing processes, including the small build volumes of most industrial 3D printers, are holding us back. Solideon will help us produce objects that are enormous by today’s standards.”

Solideon’s robotic system, Aperture, integrates multiple manufacturing steps, including wire-arc 3D printing, CNC milling, and subcomponent assembly. The computational models developed by LEAP 71, generate geometric data and process input for all the separate steps, taking the capabilities and constraints of each production method into account.

The companies are targeting several sectors, including the manufacturing of large rocket propulsion systems, as well as components for infrastructure in space.

Oluseun Taiwo, Founder and CEO of Solideon said: “A spacefaring society needs new production technologies that surpass conventional terrestrial approaches. The Aperture system combines many steps into one cohesive, autonomous, and collaborative whole. We can now manufacture large-scale objects on Earth and eventually will do so in zero gravity. By tightly integrating the engineering algorithms created by LEAP 71 with our software-driven production system, we can build objects that move space technology to a new level.”

About LEAP 71

Founded by Computational Engineering pioneers Lin Kayser and Josefine Lissner in 2023, LEAP 71 aims to transform the manual process of engineering to a software-driven approach, that creates the design of complex machines using algorithms and AI.

LEAP 71 works in a broad spectrum of fields from aerospace to electric mobility. The company’s large computational models empower engineers to build highly sophisticated parts and allows them to iterate fast, accelerating the pace of progress.

The company has open-sourced its foundational technology, PicoGK, and actively promotes a transparent and scientific approach to Computational Engineering.

LEAP 71 is headquartered in Dubai, United Arab Emirates, and works with customers globally, including in the US, Europe, and Asia. For more information, visit https://leap71.com.

About Solideon

Solideon, formerly Additive Space Technologies, leads the aerospace industry transformation with a focus on agility and reduced production times. They employ AI for generative designs and additive manufacturing improvement to enhance aerospace structure efficiency and design flexibility. Their revolutionary technology, Aperture, is an integrated robotic additive manufacturing system emphasizing vertical integration and patented 3D welding. Solideon aims to increase mission frequency through rapid refurbishment and sustainable practices, reducing reliance on external vendors and exploring advanced propulsion and launch techniques to accelerate aerospace processes while minimizing waste and costs.

For more information visit https://solideon.com.