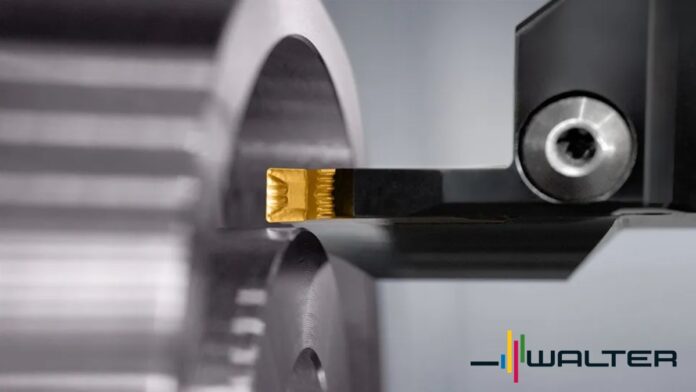

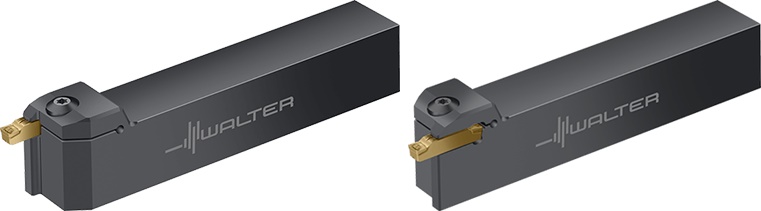

TUBINGEN, Germany, Nov 10, 2025 – Walter AG is completing its Groov·tec GD grooving tool range with new offering, making it universally applicable for all applications in grooving/parting-off, groove turning and Copy turning. Reinforced G5041 and neutral G5042 Parting blades are new to the range. Both variants are available with or without integrated Precision cooling. The range is complemented by the G5111 axial grooving system and Walter Capto turning holders (C3-C6) for the G5011 Groov·tec GD grooving system for radial grooving. Walter now offers users a particularly flexible solution for radial and axial machining: in all common materials – from steel and cast iron to difficult-to-cut materials. The system also impresses with high process reliability and performance for deep grooving operations and complex geometries.

The comprehensive product portfolio enables the user to select a universal tool for almost all diameter ranges and machining requirements. The stable Groov·tec GD serrated profile sets new standards for maximum process reliability and stability, as it increases the tool life of the indexable insert and toolholder by up to 50 %, according to Walter. At the same time, the double-serration profile enables simple and secure installation of the cutting insert and prevents it from being pushed out sideways during the operation – often a common problem in groove turning! The combination of integrated Precision cooling and double-serration also allows significantly higher cutting parameters – and thus contributes to increased efficiency. The same applies to the seven available, highly wear-resistant Tiger·tec Gold grades (3 CVD, 4 PVD), which further increase productivity. Walter offers new Walter Capto™ lathe holders G5011-C for radial machining with insert widths of 3-6 mm. Axial machining operations up to a cutting depth of 25 mm can be carried out precisely and reliably with the new G5111 tool. Walter offers the new G504… Parting blades in neutral or reinforced versions, with self-clamping or Screw clamping.

About Walter

For over 100 years, Walter has stood for competence and quality in the field of machining technology. The company was founded in 1919 by Richard Walter and has its headquarters in Tübingen, Germany. The portfolio includes precision tools for milling, turning, grooving, drilling and threading as well as individual special tools and technology solutions along the process chain. With production facilities in North and South America, Europe and Asia, numerous subsidiaries and sales partners, and 4,400 employees worldwide, Walter has a global presence and customers in more than 80 countries around the world. In addition to engineering expertise, a sustainable corporate strategy and a diversity approach are part of the corporate culture. Since 2022, the Frezite Group has been part of Walter, including the Frezite portfolio brand FMT, which deals with cutting tools for lightweight materials. For more information, visit https://www.walter-tools.com.