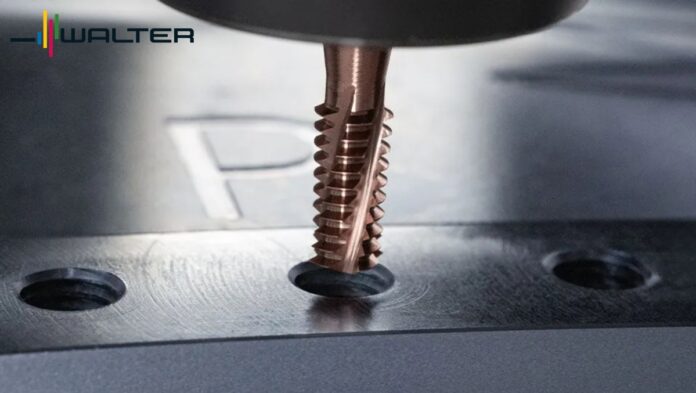

TUBINGEN, Germany, Nov 26, 2025 – With the TD610 Supreme, Walter AG presents a thread milling cutter family that sets new standards in terms of performance and process reliability. The successor to the proven TC610 Supreme not only significantly exceeds its performance and machining times in tests, but also those of the best competitors on the market to date. One of the reasons for this is the highly wear-resistant HiPIMS coating WB10TU made of AlTiSiN. It is extremely smooth, robust and wear resistant – and ensures a significantly longer service life compared to conventional coatings. In addition, the thread milling cutter has unique geometric features, such as the “trumpet bow neck”, a tapered neck and groove geometry that reduces deflection, prevents tool breakage and allows regrinding in case of wear.

The offset distribution of the flutes minimizes vibrations, especially with short threads, thereby improving thread quality and process reliability. This also applies to the special post-treatment of the TD610 Supreme, these polished cutting edges reduce wear, increase stability and improve thread quality even in the most demanding materials – while also increasing cutting speeds and reducing machining time. The full-profile thread milling cutter is universally applicable for blind and through threads in all ISO material groups, P, M, K, N and S, up to 48 HRC. Radius corrections are rare thanks to the stable process, which makes the TD610 Supreme ideal for both short-run or high-volume “lights-out” production. Walter offers the thread milling cutter for thread depths up to 1.5 × D(N), with and without internal cooling, and in many common standards like: M, MF, UNC, UNF and G. It should be of particular interest to users with demanding requirements, such as those working with expensive components.

About Walter

For over 100 years, Walter has stood for competence and quality in the field of machining technology. The company was founded in 1919 by Richard Walter and has its headquarters in Tübingen, Germany. The portfolio includes precision tools for milling, turning, grooving, drilling and threading as well as individual special tools and technology solutions along the process chain. With production facilities in North and South America, Europe and Asia, numerous subsidiaries and sales partners, and 4,400 employees worldwide, Walter has a global presence and customers in more than 80 countries around the world. In addition to engineering expertise, a sustainable corporate strategy and a diversity approach are part of the corporate culture. Since 2022, the Frezite Group has been part of Walter, including the Frezite portfolio brand FMT, which deals with cutting tools for lightweight materials. For more information, visit https://www.walter-tools.com.