HAKUSAN, Ishikawa, Japan, Aug 26, 2025 – Nakamura-Tome Precision Industry Co., Ltd. is pleased to announce the release of “NT-Flex+”, a new specification of the NT-Flex precision CNC multitasking lathe. This latest configuration features an X-axis on the R-spindle, a Y-axis on the lower turret, and an optional retractable NC tailstock, enabling a broader range of advanced machining solutions within the NT-Flex platform

With a wide array of flexible machining functions and intelligent software housed within a compact body, this machine empowers manufacturers to meet the evolving demands of the production floor.

Designed to focus on compactness, the NT-Flex has a slim machine depth of just 1,380 mm, allowing installation in tight spaces. This enables an efficient layout, making the most of limited factory space.

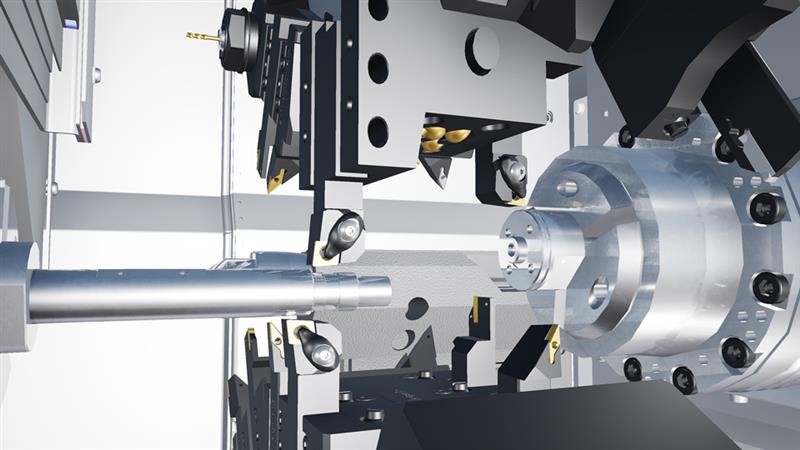

The NT-Flex is equipped with a Y-axis and milling capability (up to 10,000 min⁻¹) on the upper turret, allowing it to handle all machining processes—from turning to milling, threading, and gear cutting—in a single machine. It meets our proprietary rigidity standards, providing substantial machining capability in a compact form. This CNC lathe is versatile and can be used for various applications regardless of material.

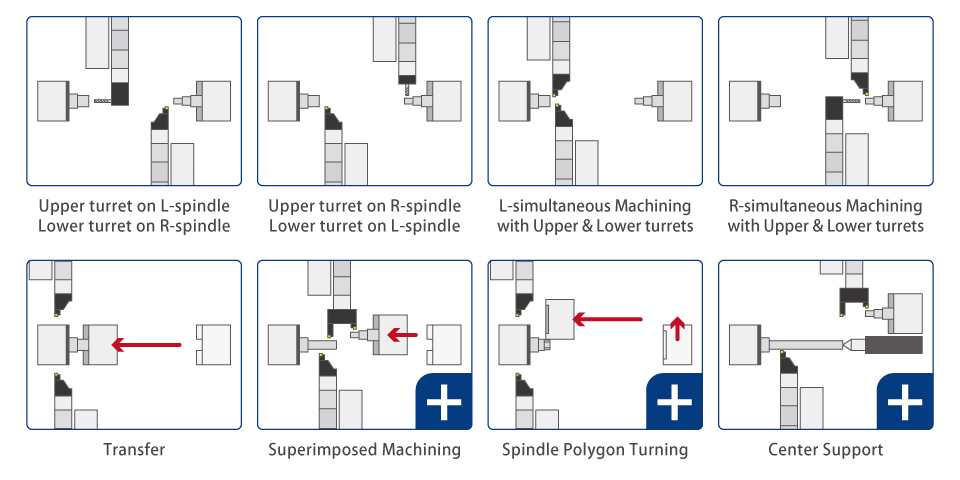

The NT-Flex+ is a new specification featuring X-axis travel on the R-spindle, Y-axis travel on the lower turret, and an optional NC tailstock. These configurations enable more complex machining patterns, including three-tool simultaneous operations.

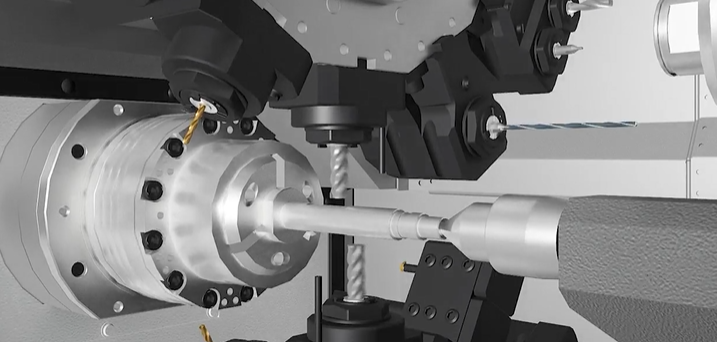

Retractable NC Tailstock

- With X-axis travel on the R-spindle, the machine offers enhanced flexibility in utilizing the internal space without interference, enabling a wider range of machining.

- The NC tailstock is normally retracted behind the R-spindle, and can be freely brought into position by moving the R-spindle in the +X direction when needed.

- This allows for simultaneous machining with the upper and lower turrets while supporting the workpiece on the L-spindle.

Machining Capability

With the addition of new features such as the X-axis travel on the R-spindle, the machine can perform various operations.

“I am delighted to announce the launch of NT-Flex+ today. NT-Flex+ is a new specification that embodies our concept of “Compact Meets Flexibility,” offering remarkable versatility in an ultra-compact size with a footprint of just 1.38 meters in depth. This machine features a two-turret (upper and lower), two-spindle (left and right) configuration, allowing simultaneous milling operations using Y-axis travel on both turrets. Additionally, the R-spindle features X-axis travel, and an optional tailstock unit can be mounted behind it, in a parallel position. I believe the name “NT-Flex+” perfectly captures the essence of this machine.”

“By utilizing the X-axis travel of the R-spindle, this machine enables simultaneous machining on both sides while firmly supporting long workpieces with the tailstock, allowing for stable processing. For customers, this means that everything from complex parts requiring milling to long workpieces that need support can be handled with just one compact NT-Flex+. In today’s rapidly changing world, we often hear from customers that the products they need to mass-produce frequently change. Therefore, I hope the NT-Flex+ will help by enabling faster and more precise automation across a wide variety of parts.”

“I truly look forward to working together with you to cut the burden of manufacturing with the NT-Flex+.” commented, Shogo Nakamura, CEO.

For more information, about precision CNC Multitasking Lathe NT-Flex, visit https://www.nakamura-tome.com/products/machines/nt-flex/

For more information, about Nakamura-Tome and its products, visit https://www.nakamura-tome.com.