[Aachen, Germany, 16 September 2025] ModuleWorks announces the upcoming market launch of its GPU Simulation. As part of the company’s strategic partnership with Sandvik, the CAD/CAM software brands Cimatron and Mastercam will be the first to make the technology available in a commercial CAM solution. The rollout is scheduled for the next releases of both Cimatron and Mastercam.

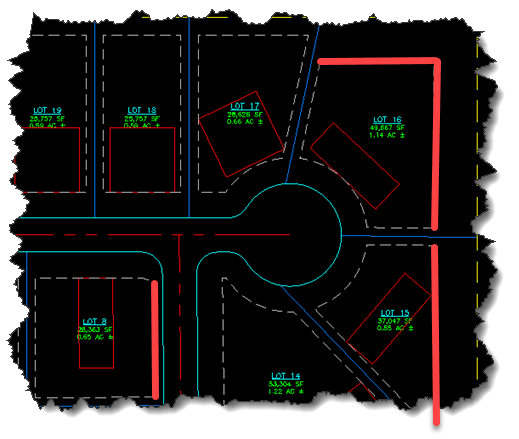

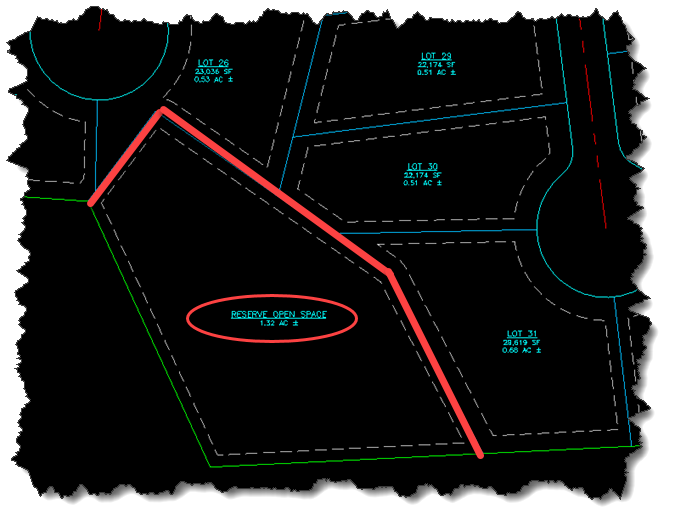

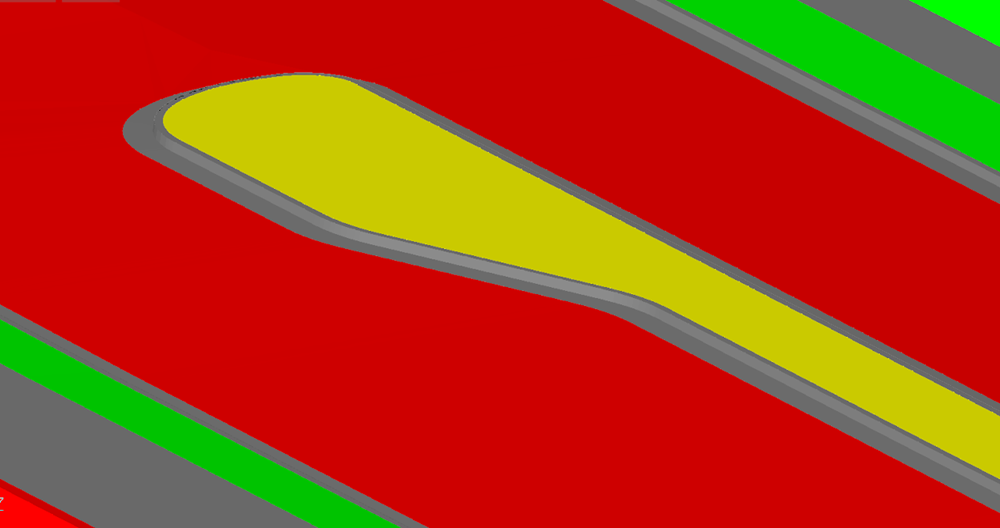

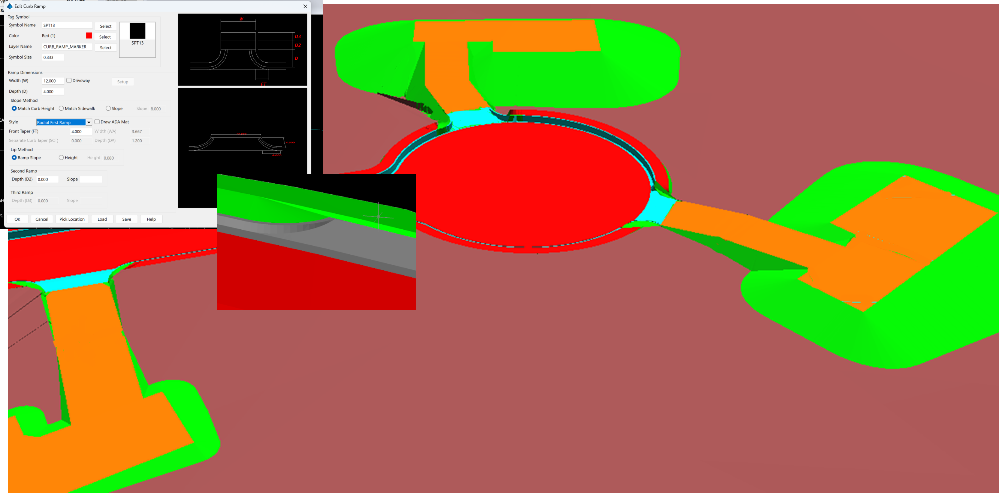

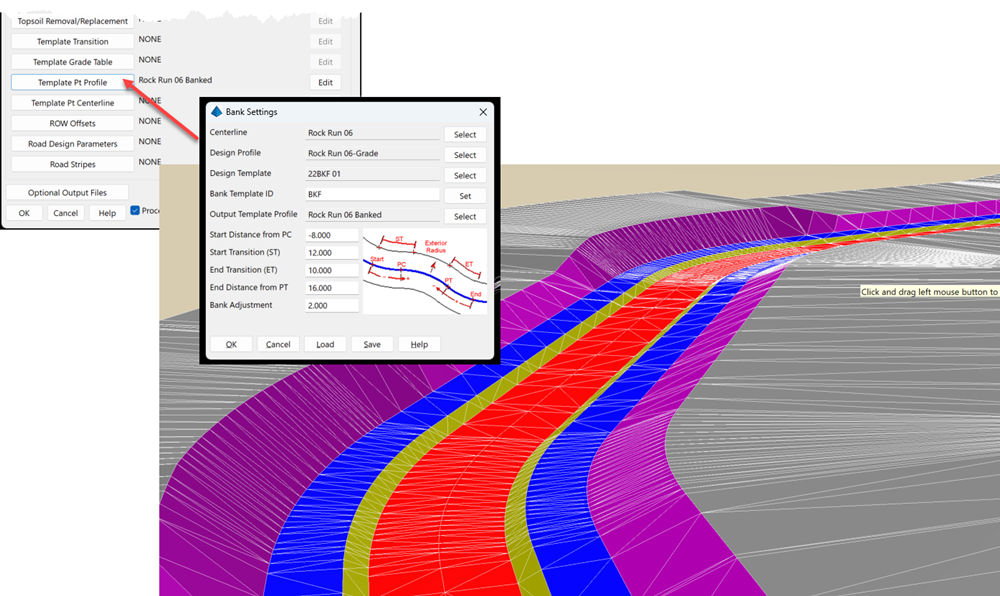

ModuleWorks GPU Simulation uses GPU-accelerated processing to increase simulation speed. Benchmark tests indicate performance improvements of up to ten times compared to CPU-based approaches1. The technology is particularly aimed at large and complex 3- and 5-axis parts, where fast verification can significantly shorten programming cycles.

Integrating GPU Simulation with the multi-axis capabilities of Cimatron and Mastercam is designed to enable more efficient verification and programming workflows and increase job throughput.

Dr. Yavuz Murtezaoglu, Founder and Managing Director of ModuleWorks:

“It’s exciting to see our GPU Simulation being rolled out in two of the industry’s leading solutions. Our strong partnership with Sandvik and their Cimatron and Mastercam brands demonstrates how collaboration can accelerate the adoption of new technologies. By working together in a strategic manner, we’re able to quickly bring real performance gains to CAM users in the production environment.”

Magnus Malmström, Chief Technology Officer, from Intelligent Manufacturing at Sandvik:

“By harnessing the massive GPU-accelerated simulation through, e.g. NVIDIA GPUs, we’re cutting toolpath verification from minutes to seconds, enabling manufacturers to work faster, safer and more efficiently. In collaboration with ModuleWorks, it comes to life now in our leading CAM solutions. This is a turning point to simplify manufacturing that empowers engineers to innovate and scale with confidence.”

Ivan Krstic, Vice President of Product, at Mastercam:

“Mastercam’s mission is to create software and services that solve the world’s manufacturing challenges. Being first to announce GPU Simulation to our user community means they will gain an immediate edge in simulation speed, power and workflow confidence, reinforcing the very advantages that have made Mastercam the world’s most widely adopted and versatile CAD/CAM solution. Whether in the classroom or on the production floor, in aerospace, automotive, or general machining, this technology will deliver tangible value to all our users.”

GPU Simulation will be incorporated into the next Mastercam release, planned for early 2026.

Simone Bonino, Global Product Director from Cimatron:

“Cimatron sets the standard for innovation in toolmaking and complex part manufacturing. Early access to GPU Simulation in our integrated CAD/CAM end-to-end solution puts our users ahead of the curve, delivering the fastest, most reliable CAM simulation and programming workflow available. This breakthrough empowers moldmakers, die designers and advanced manufacturers to handle even the toughest jobs, like machining large 3- and 5-axis mold and die components, with more speed and accuracy, helping them deliver high-quality parts, faster than ever.”

ModuleWorks GPU Simulation will be presented at EMO 2025 in Hanover, September 22–26, with hands-on demonstrations and interviews with Sandvik, Cimatron and Mastercam.

1 – Benchmark tests were conducted at the ModuleWorks facilities in Aachen, Germany using an AMD Ryzen 7 3700X CPU and NVIDIA GeForce RTX 4070 GPU which offer comparable mid-range performance. For more information and details of the test results, please contact ModuleWorks.

About ModuleWorks

ModuleWorks is at the forefront of digital manufacturing software, playing a key role in enabling the efficient production of increasingly complex parts in an environmentally sustainable way. As a strategic partner to leading CAD/CAM vendors, CNC control makers, machine tool builders and cutting tool manufacturers, ModuleWorks develops software that powers solutions throughout the manufacturing industry which contributes to 16% of global GDP worth $16 trillion per year.

Founded in 2003, ModuleWorks has grown to over 200 developers and already invested 2000 person-years of software development in toolpath and simulation technologies that form the core of manufacturing processes. In the CAD/CAM area alone, ModuleWorks has a market share of 90%, enhancing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software worldwide. With a comprehensive portfolio of cutting-edge software components and the capacity to address emerging and niche technologies like AI, cloud, automation, additive, robotics and digital dentistry, ModuleWorks is committed to shaping the future of digital manufacturing with its partners, empowering the industry to Get There Faster.

About Sandvik

Intelligent Manufacturing is a business area segment within Sandvik Group providing digital manufacturing and software solutions for design and planning automation and industrial metrology. Through our end-to-end agnostic digital offering, we automate and connect the component manufacturing value chain, from design and planning to preparation, production and verification. Visit www.manufacturingsolutions.sandvik.

About Cimatron

Part of Sandvik Group, Cimatron was founded in 1982 and has since developed the computer-aided design and manufacturing (CAD/CAM) software needed by manufacturers across industries to reach their full potential.

Serving all manufacturing sectors, Cimatron provides specialized solutions for mold and die makers, as well as comprehensive solutions for 2.5-5-axis milling and turning. Cimatron operates subsidiaries in Asia, North America, and Europe, and works with certified independent service providers in over 40 countries worldwide.

About Mastercam

Shaping the Future of Manufacturing®, Mastercam is the world’s leading provider of CAD/CAM solutions. As part of Sandvik, we empower manufacturers to enhance productivity, streamline processes, and drive innovation. With a global network of resellers and an extensive developer community, Mastercam continues to set industry standards by delivering comprehensive, connected solutions across the manufacturing enterprise. We lead the way with cutting-edge technology and unparalleled expertise. Discover more at mastercam.com.