PLANO, TX, USA, Jul 3, 2025 – Siemens Digital Industries Software announced the winners of its second annual Techcellence Awards. Launched in 2024 and continuing at Realize LIVE Europe 2025 in Amsterdam, Siemens’ Techcellence Awards brings recognition to companies and individuals that are empowering change through transformation and sustainability, as well as individuals who are leading through innovation and acting as a champion for digital technology and sharing their knowledge with the Siemens community. Winners are awarded VIP attendance passes for Realize LIVE 2026, which will take place in June 2026 in Amsterdam.

“Every day, our customers are writing the future of industry through groundbreaking digital innovations. The Siemens’ Techcellence Awards shine a spotlight on these pioneers who aren’t just embracing transformation – they’re leading it,” said Robert Jones, Chief Revenue Officer, Siemens Digital Industries Software. “From sustainable solutions to revolutionary applications of the Siemens Xcelerator portfolio, these visionaries are building a powerful community that extends far beyond Europe. They’re not just changing industries; they’re changing the world.”

The Sustainability Impact award celebrates an organization that demonstrates exceptional commitment to sustainability by leveraging Siemens technologies to drive positive environmental and social impact. It recognizes organizations that have used Siemens’ technologies to integrate decarbonization and energy efficiency practices to yield measurable impacts across the Greenhouse Gas (GHG) Protocol Emissions Scopes 1, 2 and 3.

CEE (and its sister company Ray & Jules) develops and builds clean technology for the food & beverage and building materials industries. Their innovations focus on roasting, drying, and energy recovery. Recently, they introduced an out-of-the-box alternative to conventional roasting, shifting from a batch to a high-precision continuous process. This approach uses two to three times less energy and maintains a stable energy consumption pattern, making it easier to electrify.

In 2017, they founded Ray & Jules as a separate sister company – the first coffee roaster to use their net-zero emissions roasting technology. In 2019, Ray & Jules was launched as a brand. Since then, several large roasters are following their lead, and the technology has also been applied to malt and cocoa. CEE leverages the Siemens Xcelerator platform, integrating software, hardware, and automation, to scale their sustainability impact.

The Digital Transformation award recognizes a sustainable digital enterprise that fully integrates digital technologies while driving transformation in new and innovative ways to achieve digital objectives and streamline processes faster, easier and at scale. Siemens celebrates this organization for a clear strategic vision for digital transformation by using Siemens’ solutions and aligning technology initiatives with long-term goals and objectives.

Saab AB offers a broad range of products and services, including advanced defense systems, civil security solutions, and cutting-edge technologies serving customers worldwide. The CLiQ project (Cut Lead-time, Improve Quality) at Saab Surveillance embodies a forward-looking digital transformation strategy, aiming to build a fully interconnected IT infrastructure that aligns with the company’s modernization goals in the Aerospace & Defense sector. The initiative reflects Saab’s commitment to streamlining operations through cutting-edge tools, with an emphasis on Digital Thread and Integrated Product Development to shape a smarter, more agile engineering environment. The CLiQ project has achieved impressive, indicative performance metrics including a 50 percent reduction in product data management time and a 75 percent reduction in material management time, demonstrating how the initiative has drastically improved operational efficiency. It has also eliminated over 70 percent of manual tasks, enabling employees to focus on strategic, high-value work and boosting productivity and innovation across teams.

The Community Champion award recognizes an individual who has gone above and beyond by sharing his or her expertise with Siemens technology. The Siemens community champion exhibits exemplary community leadership through their substantial public contributions. This award honors an individual who helps peers by sharing their knowledge by providing answers, speaking at events and creating publications while championing Siemens products and providing valuable feedback and insight to make the products better. The Siemens community champion exhibits exemplary community leadership through their substantial public contributions.

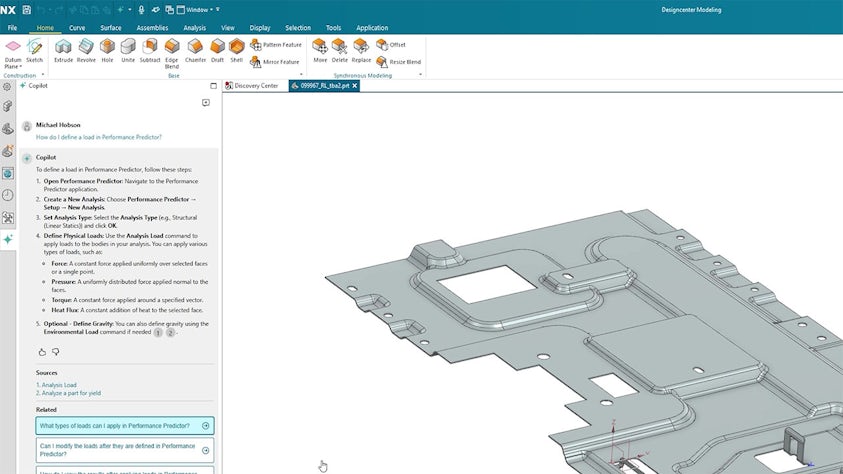

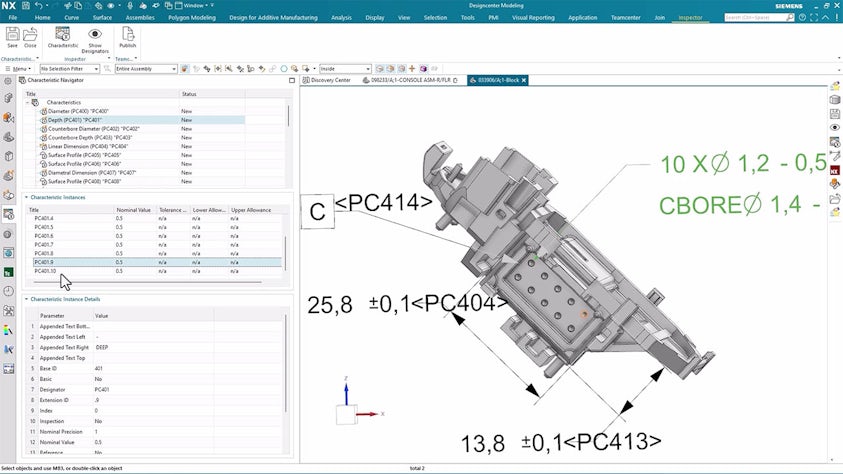

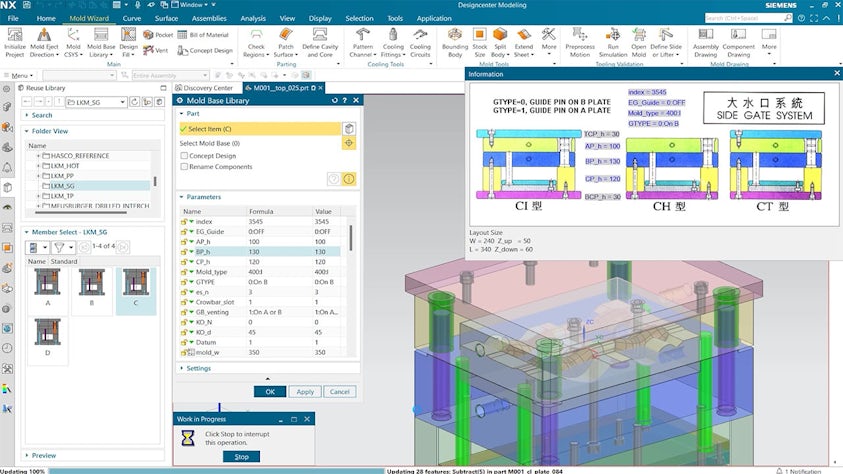

Frederik Vanhee, founder of theScriptingEngineer and active Youtuber, is an NXOpen specialist in the Benelux region, supporting users worldwide in the forums. He works at the intersection of engineering, data, and IIoT, and helps marine and offshore companies digitize their engineering workflows. Vanhee hosts the largest public NXOpen repository and has contributed over 200 responses to NXOpen users in the Siemens Digital Industries Software forums, providing 38 best answers to assist his peers.

The Innovation Leader award honors Siemens’ customers who exemplify creativity and forward-thinking by driving transformative change within their industries. These trailblazers are generating groundbreaking ideas, products or processes that redefine what is possible. We recognize and celebrate these customers that leverage Siemens technologies and solutions to drive organizational progress.

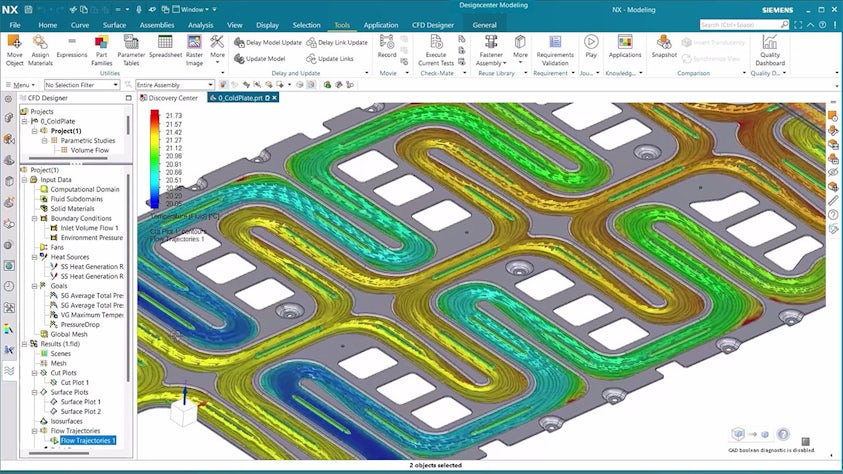

Wolfram Kühnel, head of 3D Simulation at MAHLE International GmbH leads an engineering team that specializes in Computational Fluid Dynamics and uses Siemens solutions to create innovative products. MAHLE has been shifting toward e-mobility, which, while challenging, has resulted in the creation of new products such as the Bionic Battery Cooling Plate or the Bionic Fan, both of which were presented for example at CES 2025. Kühnel leads a team of CFD specialists to broaden the range of simulations for enhancing the development at MAHLE – simulating thermal management and electromobility devices and optimizing HVAC units. His team is at the forefront of technology and collaborates closely with universities and Siemens to continue to push the boundaries of technology and is leading the innovation transformation at MAHLE.

This follows the Techcellence Awards for Realize LIVE Americas, announced at the event earlier this month in Detroit. To learn more about the 2025 finalists and winners of the Techellence Awards and how to nominate for 2026, visit https://events.sw.siemens.com/en-US/realizelive/techcellence-awards/

About Siemens Digital Industries Software

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.