LAS VEGAS, NV, USA, Jun 19, 2025 – Hexagon’s Manufacturing Intelligence Division today announces a major release of ESPRIT EDGE, its industry-leading computer-aided manufacturing (CAM) software, addressing productivity and skills challenges with extensive user-friendly swiss machining support and the first AI services powered by Hexagon’s cloud based Nexus platform.

This new release introduces ground-breaking advancements in Swiss machining and artificial intelligence (AI), empowering manufacturers to overcome programming complexity and address the widening skills gap, enhance productivity and streamline operations to meet the evolving needs of modern, high precision production environments.

Democratising Swiss Machining Functionality

For the first time, ESPRIT EDGE introduces Swiss machining functionality, enabling safe, efficient and simplified programming for complex machines such as CITIZEN L-series and STAR SR-Series. An intelligent digital twin acts as a precise virtual model of the machine, enabling advanced features like superimposition, composite axis control, and automatic prepositioning to optimise performance and ensure collision-free operations.

With tools for configuring collets, guide bushings, and tool mounting blocks, ESPRIT EGDE reduces user expertise requirements whilst making set-up faster and more consistent. Features such as automatic synchronisation, adaptive cycles and tilted plane rotation simplify programming for multi-channel operations, minimising manual coding and errors.

Real-time simulation ensures safe and highly accurate, optimised machining, while high-quality, OEM-tailored G-code eliminates post-processor customisation.

These advanced and extremely versatile capabilities mean ESPRIT EDGE successfully addresses the challenges of Swiss machining, including complex kinematics, limited CAM support, and the imposition of steep learning curves for machinists, making it easier for shops to adopt high-precision technology.

AI-Powered Automation Tools

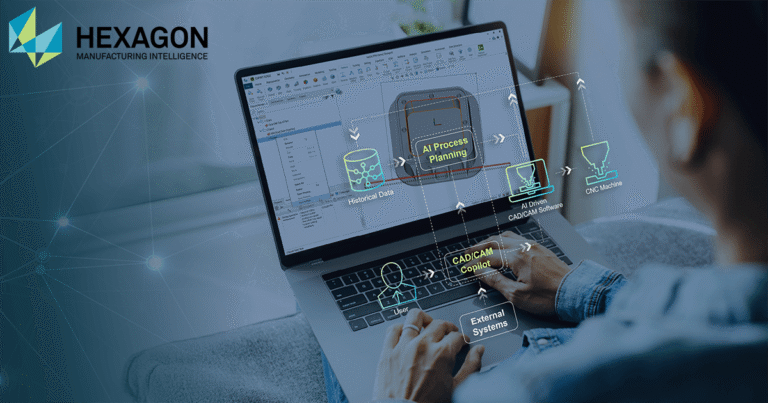

Leveraging AI to transform CAM programming with two innovative tools, ESPRIT EDGE empowers manufacturers to automate repetitive tasks, reduce errors, and improve overall efficiency, enabling faster time-to-market for their products.

Firstly, Hexagon Copilot, an AI-driven virtual assistant, provides 24/7 support for CAM programmers of all skill levels. With natural language processing, it offers tailored responses, expert guidance, and seamless integration into the software’s interface.

Secondly, ProPlanAI streamlines process planning and accelerates production. It is a self-learning automation tool that uses historical machining data to predict and optimise processes for new parts, minimising manual intervention.

Overcoming The Skills Gap with AI and Knowledge Capture

With the skills gap impacting the manufacturing industry on a global scale, ESPRIT EDGE utilises AI-driven solutions to bridge this gap, making CAM programming accessible to users of all experience levels.

With the focus on knowledge retention and sharing, Hexagon Copilot and ProPlanAI fully leverage institutional insight and experience, ensuring expertise remains within the organisation even as experienced employees retire or leave.

Using these capabilities, new programmers quickly become productive by relying on intuitive AI tools, reducing the training time and resources they need to become proficient. These innovations enable manufacturers to standardise processes, reduce workflow disruptions, and maintain consistent quality across their operations.

“With the release of ESPRIT EDGE 2025, we’re reaffirming Hexagon’s commitment to driving innovation in manufacturing,” said Chuck Mathews, General Manager Production Software at Hexagon Manufacturing Intelligence. “By combining advanced Swiss machining capabilities with cutting-edge AI technologies, this latest version empowers manufacturers to overcome today’s challenges – from the scarcity of skilled machine operators to the intense demand for greater productivity. It’s all-in-one revolution in CAM programming, Swiss-type machining and AI automation will help manufactures stay competitive, agile and achieve new levels of efficiency.”

ESPRIT 2000 and ESPRIT EDGE customers can upgrade to ESPRIT EDGE 2025.2 to access the latest desktop software capabilities and access ProPlanAI via Nexus. For more information, please visit https://hexagon.com/products/esprit-edge or contact your local Hexagon sales representative.

About Hexagon

Hexagon is the global leader in precision technologies at any scale. Our digital twins, robotics and AI solutions are transforming the industries that shape our reality.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 24,800 employees in 50 countries and net sales of approximately 5.4bn EUR. Learn more at hexagon.com and follow us @HexagonAB.