QUEBEC, QC, Canada, Jun 12, 2025 – InnovMetric is proud to announce a new PolyWorks Digital Thread partnership program. In collaboration with software companies that develop and commercialize solutions for engineering, manufacturing, and quality, this new program aims to accelerate the digitalization of manufacturing processes. It achieves this by creating an interconnected network that drives dimensional inspection data interoperability from a single source of truth with effortless digital data flows between software applications.

Manufacturing organizations must ensure that data flows from one software to another as they rely on best-in-class solutions from multiple vendors for the digitalization of their manufacturing processes. While functional, the typical file-based data exchanges used within the dimensional management process between engineering, manufacturing, and quality present major data-flow issues, including having multiple copies of the same dimensional inspection information in multiple locations. The PolyWorks digital thread enables partners to digitally interconnect their software solutions to the PolyWorks universal metrology software platform and centralized data management server. It also allows automating the data flows that deliver dimensional inspection inputs to quality and leverage digital twin instances as well as 3D measurement data outputs enterprisewide.

“Our existing PolyWorks connectors cover a wide array of applications and processes and we plan to add more connectors in the future. However, the use of 3D measurement data is expanding, and the number of applications that could benefit from it is rising as well. So, we think that the task is too big to solely rest on our shoulders. This is why we have decided to partner with software companies to allow them to develop and commercialize digital connectors that exchange 3D measurement information between PolyWorks and their own solutions,” says Marc Soucy, President of InnovMetric. He concludes, “It was natural for us to take this decision, as we had already determined that PolyWorks would be an open solution.”

InnovMetric is proud to onboard and collaborate with its first digital thread business partners: High QA, AutoForm, and Duwe-3d.

High QA

High QA is a leading provider of integrated manufacturing quality management software solutions for any size company in all major manufacturing industries. Its software optimizes and automates the entire quality assurance process through automated data extraction and contextualization, creating a clear, traceable, and consistent bill of characteristics (BoC).

Its first PolyWorks digital thread connector, now available, is built into their HQA Connect software, which allows quality assurance and manufacturing specialists to automatically balloon 2D drawings using optical character recognition (OCR). This connector enables metrologists to automatically synchronize dimensional requirements from these ballooned drawings to PolyWorks|Inspector™. With such seamless digital integration, inspection projects can be created in record time, eliminating drawing interpretation errors while maintaining complete data integrity.

High QA plans to further extend the interconnection between HQA Connect and PolyWorks by streaming inspection results from the PolyWorks|DataLoop™ centralized 3D measurement server to automatically populate quality assurance reports, such as FAIs and PPAPs, within their 360 Core reporting and analysis software solution.

“Together with InnovMetric, we’re weaving a digital thread that connects your quality and manufacturing teams, empowering them to work smarter, faster, and with greater accuracy,” says Sam Golan, Founder and CEO of High QA.

For more information on digitalized drawing inputs to dimensional inspections, contact High QA by email or call +1-888-727-1266.

AutoForm

AutoForm is a leading provider of software solutions for stamping and body-in-white (BiW) assembly process. They allow defining the optimal scenario during process engineering stage to avoid costly and time-consuming quality loops at the prototype and production phases.

The PolyWorks digital thread partnership with AutoForm empowers automotive manufacturers to perform virtual dimensional inspections in PolyWorks|Inspector based on simulation models generated by AutoForm Forming and AutoForm Assembly at the process engineering phase. Inspection data and measurement results are made accessible to quality and engineering teams in real-time using the PolyWorks|DataLoop centralized 3D measurement server.

Available now, this new digital twin and 3D measurement-based process significantly reduces the number of tooling and assembly process iterations. It also allows process engineers and quality experts to detect dimensional issues 12 to 18 months before any tooling and part production. Engineering teams can leverage more detailed deviation analyses between simulated models and nominal dimensions to further improve simulation efficiency.

“Today, optimizing process engineering by building a digital twin-based process, customers save around five million euros per year per car project. We are confident that bringing dimensional inspection early into the process engineering phase will save a couple of million more,” states Olivier Leteurtre, CEO of AutoForm.

For more information on the engineering simulation-based virtual inspection process, contact AutoForm.

Duwe-3d

Duwe-3d has been a business partner of InnovMetric for 25 years. As the exclusive PolyWorks Master distributor for Germany, Austria, and Switzerland, Duwe-3d provides customers with bespoke PolyWorks software extensions that meet specific requirements and applications.

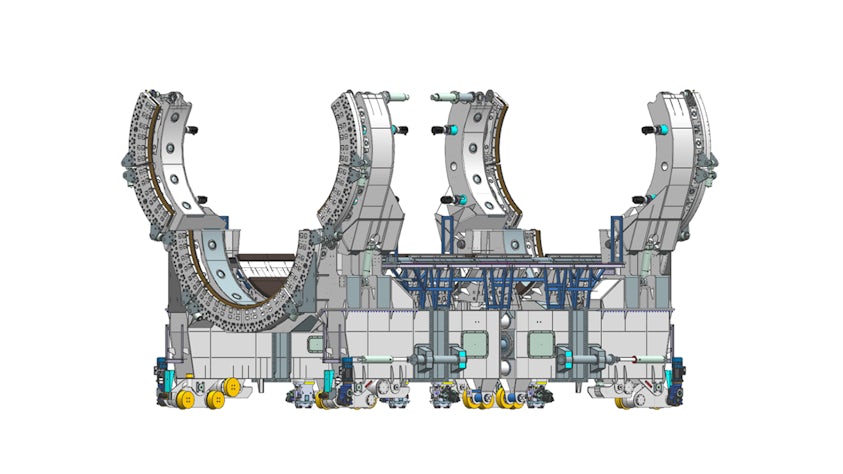

Extending the business relationship to the PolyWorks digital thread partnership was sparked by the development of an experimental virtual clamping plug-in for PolyWorks|Inspector, designed to streamline the inspection process of stamped parts. By applying virtual clamping forces through simulation software, this plug-in allows deforming the 3D scanned model of an unconstrained sheet metal piece as if the piece was physically clamped. This tool eliminates the need to build checking fixtures for individual sheet metal parts, accelerating inspections and reducing tooling costs.

“Our customer ‘Porsche Leipzig’ is already virtually clamping their parts and checking them in PolyWorks. Proof of Concepts for other OEM’s have shown cost & time savings of up to 60%,” says Claus Knoll, CEO of Duwe-3d.

While it is still in the beta testing stage, the virtual clamping plug-in is set to be commercially available later this year. For more information, contact Duwe-3d.

InnovMetric is in discussions with additional companies to keep expanding the PolyWorks Digital Thread partner program, offering manufacturers a single source of truth for their dimensional inspection data enterprisewide.

About InnovMetric

InnovMetric is an independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes. InnovMetric has revolutionized 3D metrology with the introduction of point-cloud-based dimensional inspection in 2000 and the concept of a universal 3D metrology software platform in 2006.

Today, with over 23,000 customers in 100 countries, and the world’s largest industrial manufacturers having adopted its PolyWorks® solutions as their standard 3D metrology software platform, InnovMetric is focusing on creating next-generation digital data and process management technologies.

Watch this video to discover the story behind InnovMetric’s mission, people, and passion for innovation.