BOSTON, MA and DEARBORN, MI, USA, Mar 3, 2021 – Desktop Metal, Inc. (NYSE: DM), a leader in mass production and turnkey additive manufacturing solutions, announced it has completed the previously announced acquisition of EnvisionTEC, a leading global provider of volume production photopolymer 3D printing solutions for end-use parts. The transaction is valued at $300 million, consisting of a combination of cash and Desktop Metal stock and subject to customary adjustment.

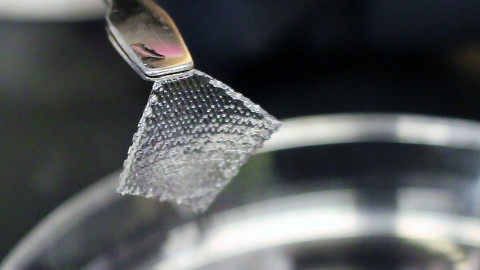

Desktop Metal acquires EnvisionTEC, a leading global provider of volume production photopolymer 3D printing solutions for end-use parts, and a pioneer in digital biofabrication additive manufacturing for the production of biocompatible parts for medical applications such as bone regeneration, cartilage regeneration, soft tissue fabrication, drug release, and organ printing.

EnvisionTEC will operate as a wholly owned subsidiary of Desktop Metal and continue to be led by founder Al Siblani, who will serve as Chief Executive Officer of the EnvisionTEC business.

“With EnvisionTEC now a part of Desktop Metal, we are well positioned to offer customers a complete platform across polymers and metals, focused on Additive Manufacturing 2.0 solutions for volume production of end-use parts,” said Ric Fulop, CEO and co-founder of Desktop Metal. “Together, we have more than 200 distribution partners around the world that extend our reach into applications across fast-growing markets for additive manufacturing, such as dental, medical, and jewelry, in addition to doubling down on the broader industrial market. As we join forces, I’m more confident than ever we can accelerate the adoption of AM 2.0 and help customers transform how parts are made around the world.”

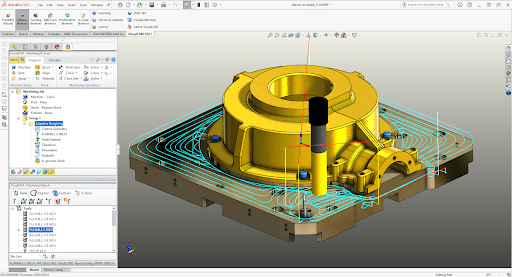

As the original inventor of digital light processing (DLP) 3D printing technology, EnvisionTEC has one of the strongest intellectual property portfolios in the area-wide photopolymer 3D printing market, counting more than 140 issued and pending patents. The company has in excess of 190 qualified materials for its platforms and more than 5,000 customers across a broad range of industries, including automotive, aerospace, medical devices, jewelry, and biofabrication. In addition, EnvisionTEC is a leader in the dental market, with over 1,000 dental customers now using its printers for pre-production and end-use parts in this segment.

EnvisionTEC also brings a compelling product portfolio for photopolymer additive manufacturing under Desktop Metal’s umbrella, including the new Envision One and Xtreme 8K printing platforms designed to deliver high-speed and economic end-use parts production with exceptional accuracy and properties meeting or exceeding thermoplastics. The company is a pioneer in digital biofabrication additive manufacturing with its Bioplotter platform, which supports the production of biocompatible parts for medical applications such as bone regeneration, cartilage regeneration, soft tissue fabrication, drug release, and organ printing. In addition, Desktop Metal adds EnvisionTEC’s robotic additive manufacturing (RAM) digital casting capabilities, which it plans to significantly advance using its proprietary and patent-pending Single Pass Jetting™ technology originally developed for the Production System to drive productivity enhancements and improve part economics.

The acquisition more than doubles Desktop Metal’s global distribution network, adding vertically focused partners in markets such as medical, dental, and jewelry, and increasing its geographic sales capabilities to 68 countries around the world.

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum and named to MIT Technology Review’s list of 50 Smartest Companies. For more information, visit www.desktopmetal.com.

About EnvisionTEC

EnvisionTEC is a leading global provider of professional-grade 3D printing solutions. Founded in 2002 with its pioneering commercial DLP printing technology, EnvisionTEC now sells more than 30 printer configurations based on five distinct technologies that build objects from digital design files. The company’s premium 3D printers serve a variety of medical, professional and industrial markets, and are valued for precision, surface quality, functionality and speed. For more information, visit www.envisiontec.com.

Born from a collaboration with Henry Ford Health Systems, Materialise Enlight brings the benefits of 3D planning to left atrium appendage occlusion

Born from a collaboration with Henry Ford Health Systems, Materialise Enlight brings the benefits of 3D planning to left atrium appendage occlusion