BROOMFIELD, CO, USA, Apr 29, 2020 – Spatial Corp, the leading provider of 3D software development toolkits for design, manufacturing, and engineering solutions, and a subsidiary of Dassault Systèmes, announces the production release of 2020 1.0.1. The release 2020 1.0.1 enables hybrid manufacturing workflows, improved application responsiveness, and enhanced robustness for simulation workflows.

Enable super-fast review of large models

Selective import for optimal performance

3D InterOp’s selective import ability lets you optimize your data preparation application for handling large CAD models.

Your application can start by just importing the data required for visualization of the large CAD model, which with latest improvements typically takes a few seconds (see details below). This means that your users can start reviewing large models within seconds of uploading them in your application.

While your users review the model, your application can start loading exact BRep data in the background. It can also allow your users to isolate and selectively import exact BRep for just a few parts in the large assembly, and continue the workflow without having to re-start the process.

Solidworks and CATIA together make up the majority1 of the PLM suppliers for C-Design (CAD/CAM/CAE/ECAD). Hence, in the 2020 1.0.1 release, we have radically enhanced the performance of visualization2 import from SolidWorks and CATIA parts and assemblies by up to 17 times. See the performance chart below for more details.

*1 – 2019 ARC PLM Market Results

*2 – SPAlopVisu… interfaces

To replicate these gains, set these CATIA and SOLIDWORKS import options.

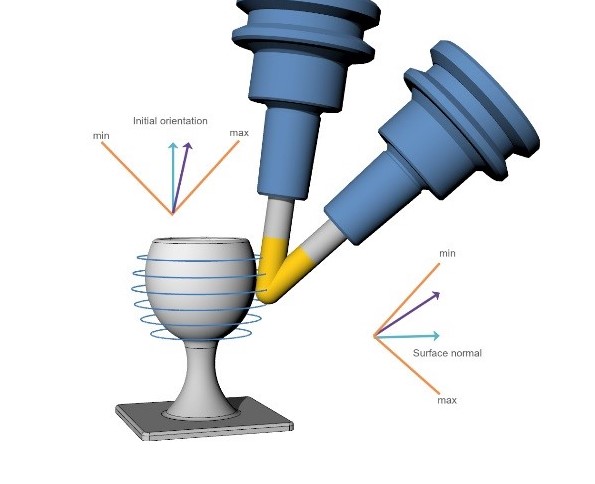

Expand the scope of your application to enable hybrid manufacturing

Expand the Scope of a 3D Modeler

Operate on hybrid sets of data and perform both additive and subtractive manufacturing processes by leveraging CGM’s exact and polyhedral geometry modeling capabilities.

Enable your users to work with data designed in a CAD tool or generated by scanning a real 3D object. Prepare geometry for 3D printing by leveraging wall thickness analysis and offset operators to produce light-weight yet printable parts.

With the 2020 1.0.1 release, the following CGM operators can be used in hybrid workflows:

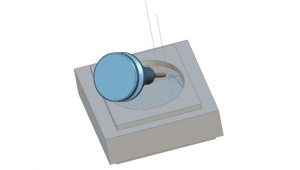

Customize a scanned part with hybrid geometric operators for Additive manufacturing.

Customize a scanned part with hybrid geometric operators for Additive manufacturing.

Hollowing using rolling ball offset

Hollowing using rolling ball offset

Add simulation to your application

Modular Workflow Solutions

Spatial’s modular SDKs enable you to add simulation to a new or existing application with minimal development effort.

Save time to focus on your differentiators by leveraging Spatial’s robust Booleans and meshing solutions for your data preparation needs. Spatial’s solution gives your application automatic CAD Associativity to the mesh, as well as the ability to automatically identify interfaces (contacts) between different domains, so your users can focus on their simulation.

In 2020 1.0.1, we have enhanced the robustness of CGM’s non-regularized unite for exact geometry. It is now better suited to support interface generation and identification between different bodies in a CAD model thus allowing for automation in data preparation for CHT (Conjugate heat transfer), CFD (Computational fluid dynamics) etc. simulations.

Automatic interface generation and identification

Automatic interface generation and identification

ACIS, a proven modeler, further enhances booleans

Enhance the Experience of Existing ACIS Applications: Proven Modeler

ACIS applications are the most proven and robust on the market. With 30 years of continuous development, ACIS provides its customers a stable, flexible and performant experience.

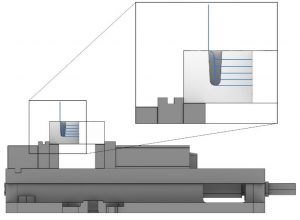

With 2020 1.0.1, 3D ACIS Modeler is more stable at performing incremental Booleans (iterative Booleans that offer a higher rate of success than 1-step Booleans) when dealing with bad geometry like sliver faces, edge-face near coincidence etc. With a more robust preparation step, incremental Booleans deliver consistent success rates for complex and noisy data sets. This is especially relevant for ACIS based Simulation applications that perform multi-body Booleans.

Sliver Face Interaction: Sliver Face Can Be Present in Tool or Blank and It Is Interacting Other Body

Sliver Face Interaction: Sliver Face Can Be Present in Tool or Blank and It Is Interacting Other Body

Spatial is a solution advisor, not just a component provider

Enhance the Experience of Existing ACIS Applications: Solution Advisor

2020 1.0.1 release includes ACIS enhancements delivered as a result of direct engagements with ACIS customers. By leveraging Spatial’s 3D experts in the customer success team, you can get custom implementations done for your needs and strategies or schedule on-site trainings. To get started, contact your Account Manager or reach us at the support portal.

Some such 2020 1.0.1 enhancements include:

Up to 65% performance improvements in wrapping a large number of wire bodies on a face (api_wrap) by enabling multithreading. This can allow for real-time marking, engraving or etching of 3D objects.

Reverse engineer point segments to generate line and arc segments.

This functionality can enable applications focused on converting scanned data to BRep or exact geometry.

Applications:

- Easy editing downstream

- Speed up 3D printing or robotic arm movement

Other highlights in 2020 1.0.1

3D InterOp:

- CATIA V5 threads are now supported for all 3 modeler flavors of 3D InterOp.

- The demo tool, 3DScript has been enhanced to support new 3D InterOp interfaces:

- Multi-process import

- Activation of minimal data import policy to get high performance, and more

- New UConnect focused portal in documentation to help you adopt the new interface. More enhancements to this page will be coming soon. We will also continue to maintain and enhance the former Connect interface focused portal.

- Updated CAD version support:

- CATIA V5-6 R2020

- NX 1872 and 1899

- Parasolid 32.0.152

- JT 10.3 & 10.5

- Revit 2019

- PMI from Solidworks 2020

Refer to the 3D InterOp release notes for a complete list of updates

CGM:

- An updated list of hybrid operators is available here. Now you can perform splits, intersections, disconnect a group of wires, extract boundaries, create silhouette etc. on both exact BRep as well as polyhedral inputs.

- 3D Precise mesh, bridge between CGM and Distene MeshGems, supports any MeshGems version from 2.4 to 2.10.

Refer to the CGM release notes for a complete list of updates

ACIS:

- ACIS-HOOPS Bridge has been updated to support HOOPS Visualize 3DF API v24.10 on all platforms

- Generate miter faces when thickening connected sheets to create manufacturable parts

- Continued effort to prevent generation of zero-length edges from most ACIS algorithms as well as successfully handling them in legacy models

Refer to the ACIS release notes for a complete list of updates

About Spatial

Spatial Corp, a Dassault Systèmes subsidiary, is the leading provider of 3D software development toolkits for technical applications across a broad range of industries. Spatial 3D modeling, 3D visualization, and CAD translation software development toolkits help application developers deliver market-leading products, maintain focus on core competencies, and reduce time-to-market. For over 30 years, Spatial’s 3D software development toolkits have been adopted by many of the world’s most recognized software developers, manufacturers, research institutes, and universities. Headquartered in Broomfield, Colorado, Spatial has offices in the USA, Germany, Japan, China, and the United Kingdom. For more information, visit www.spatial.com.

Unpacking of 3D printed headbands for face shields

Unpacking of 3D printed headbands for face shields

Drag convergence with and without the convergence booster

Drag convergence with and without the convergence booster Convergence checker interface

Convergence checker interface ONRT Turning circle

ONRT Turning circle

An insulated-gate bipolar transistor thermal simulation with Simcenter FLOEFD, ready for a BCI-ROM extraction.

An insulated-gate bipolar transistor thermal simulation with Simcenter FLOEFD, ready for a BCI-ROM extraction.

Customize a scanned part with hybrid geometric operators for Additive manufacturing.

Customize a scanned part with hybrid geometric operators for Additive manufacturing. Hollowing using rolling ball offset

Hollowing using rolling ball offset

Automatic interface generation and identification

Automatic interface generation and identification Sliver Face Interaction: Sliver Face Can Be Present in Tool or Blank and It Is Interacting Other Body

Sliver Face Interaction: Sliver Face Can Be Present in Tool or Blank and It Is Interacting Other Body