Introduction

Time Domain Reflectometry (TDR) is a powerful diagnostic technique used to detect impedance discontinuities and faults in transmission lines. In this study, we demonstrate how CST Studio Suite enables accurate TDR analysis of a coaxial cable, helping engineers visualize and locate imperfections with high precision.

Simulation Setup

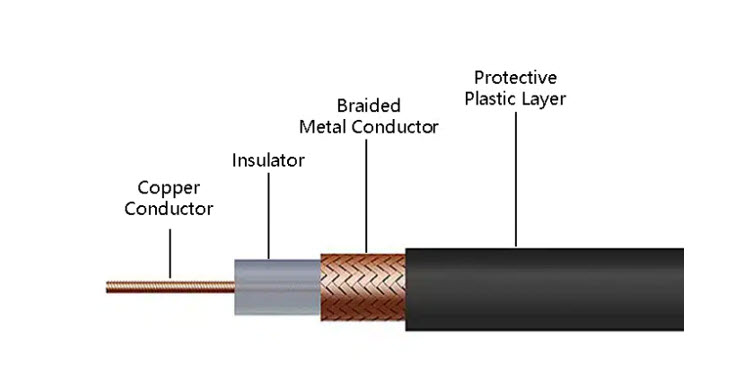

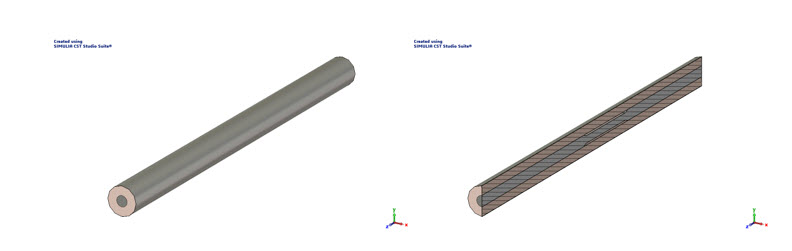

The simulation was performed on a 100 mm coaxial cable model. The inner conductor has a diameter of 2.74 mm, and the outer conductor starts at a radius of 3.62 mm from the center, with a thickness of 35 µm. The space between the conductors is filled with PTFE dielectric material. A fault was introduced by clipping a portion of the inner conductor and inserting a smaller conductor of 0.05 mm radius using the loft operation. Waveguide ports were placed on both ends of the cable for excitation and monitoring.

CST Features Demonstrated

The CST Studio Suite simulation utilized several advanced features:

– Time Domain Solver for TDR analysis

– Power Flow Monitoring to visualize energy propagation

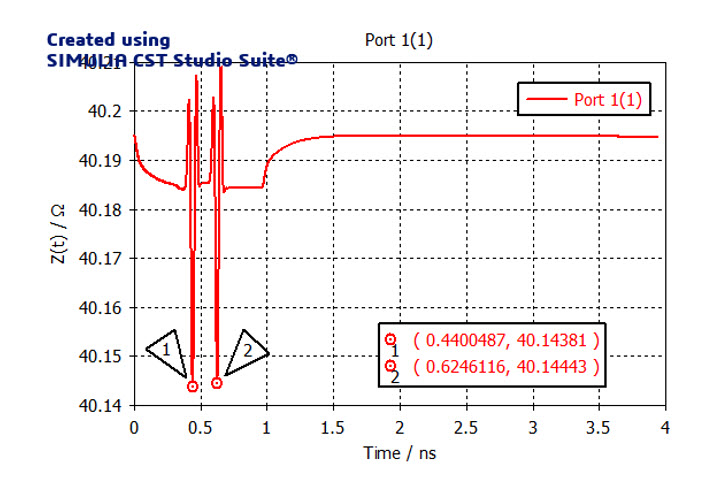

– Impedance vs Time curve to detect discontinuities

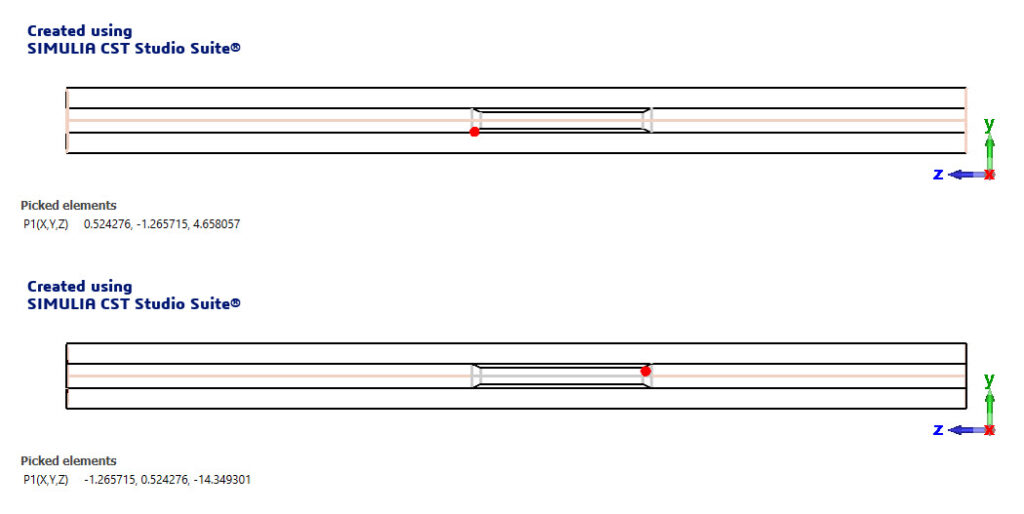

– Cross-probing with VBA macros to correlate impedance spikes with physical locations

– Post-processing templates for automated fault distance calculation

Results

The TDR analysis revealed impedance imperfections in the cable. The impedance vs time curve showed clear reflection spikes corresponding to the fault location. Using CST’s cross-probing technique, the exact physical location of the fault was identified. The fault distance was calculated using the formula:

d = (v × t) / 2, where v = c / √εr

Here, εr is the dielectric constant of PTFE (≈ 2.1), and c is the speed of light.

Why It Matters

TDR analysis is essential in industries such as aerospace, telecommunications, and automotive for ensuring signal integrity and detecting manufacturing defects. CST Studio Suite provides a comprehensive workflow for modeling, simulating, and analyzing such scenarios with high accuracy, making it a valuable tool for engineers and researchers.

Guest Post by BEACON India – Author: B N BalaRami Reddy, Sr. Application Engineer – Electromagnetics