- The printer is poised to provide cost saving of 80% for polymer 3D printing and deliver CNC machined part with 70% reduced cycle time

- It is the first “Made In India” agile on demand manufacturing machine

- 3D Printing, CNC Milling all in one machine with metals, ceramics, gels and Polymer

Mumbai, 08 September, 2022:

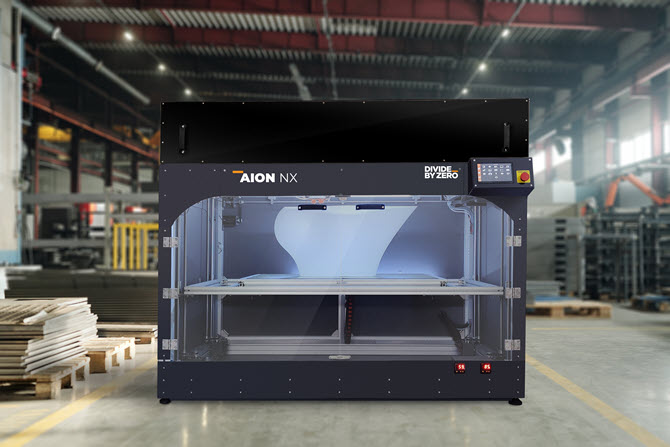

Divide by Zero Technologies (DBZ), one of India’s leading 3D Printer manufacturers, has launched AION NX, the next frontier in large format hybrid 3D printing. AION NX addresses the needs of pattern and mould makers, large component manufacturers of automobile, defence, aerospace, and innovators in the Research & Development sectors. With the largest bed size in its class, custom extrusion heads and hybrid machining capabilities, the AION NX allows manufacturers to print large components of up to 1 metre in a single setting.

Resulting into cost saving of 80% for polymer 3D printing (as the machine uses direct pallet extrusion 3D printing) and deliver CNC machined part with 70% reduced cycle time.

Developed under the “Make In India” campaign, AION NX has been developed by DBZ to address the challenges faced by the R&D and small volume manufacturing sectors who need to reduce prototyping and manufacturing lead times while ensuring the quality and finish of the component are up to standard.

The AION NX 3D printer comes with multiple features, many of which are the first in the 3D printing industry. The flagship 3D Printer is available as a Completely Knock Down (CKD) Kit, making it easy to transport and assemble. The machine features customisable extrusion heads to allow printing with paste, gel and ceramic materials, coupled with multiple automation options, and the capability to print up to 1 meter.

On the occasion of the launch, Swapnil Sansare, CEO of Divide By Zero, said, “The AION NX truly knows no limits. A lot of thought, research and innovation efforts has gone into the development and we have worked extensively on the core hardware software engine of this machine to make sure that it delivers on its promises. We have developed the AION NX, keeping in mind New Product Development teams, Researchers & New Start-ups with the view to help them convert their ideas into reality faster and without limits.”

New Product Development and R&D teams need the capability to rapidly develop and test prototypes with various materials. The AION NX features multiple extrusion options to support a wide variety of gels, polymers and ceramic materials. Moreover, the hybrid pallet head allows teams to finish their prototypes with a CNC milling head or laser cutter – thus making rapid prototyping truly rapid.

The large bed size and multiple extruder options also make production easier for large automotive component manufacturers, aerospace and drone manufacturers and other similar industry sectors that need to print complex carbon fibre parts or large patterns in a single setting.

ABOUT DIVIDE BY ZERO TECHNOLOGIES

Divide By Zero is one of India’s premier homegrown manufacturers of high-speed and cost-effective 3D printing machines. Under the “Make in India” banner, we are the first Indian manufacturer to export 3D printers globally. We hold multiple patents for our machines and technology, making Divide By Zero Technologies a disruptor in the on-demand small-volume manufacturing sector. We also play a major role in the education sector, working with various universities across India to successfully incubate 500+ start-ups.

We support more than 800+ companies and institutes across industries including Tata Group, Mercedes-Benz, Samsung, DRDO, Godrej, HUL, Whirlpool, Ola Electric and 1000+ start-ups across multiple countries for all their 3D printing requirements.

Links:

Website: https://www.divbyz.com/

AION NX webpage: https://www.divbyz.com/campaigns/aion-nx/

LinkedIn: Divide By Zero Technologies | 3D Printing.