The more opportunities metal additive manufacturing opens up to improve manufacturing capability, the more challenges industry professionals face on their way to reach material and cost efficiency, design flexibility, and better performance of their solutions.

Looking to overcome the limitations of existing additive manufacturing (AM) technology and unlock AM’s full potential, Desktop Metal, an award-winning metal 3D printer manufacturer, turned to AMC Bridge to advance the Live Parts™ solution for real-time shaping of metal parts.

PROJECT HIGHLIGHTS- The client’s solution evolved from the initial desktop application to a complex SaaS/PaaS solution

- Real-time generative design of metal parts

- NVIDIA CUDA® GPU–accelerated implementation for cloud modeling and simulation

- Integration of the existing technology in the SOLIDWORKS® CAD 3D package

- Development of a web application to control Live Parts deployment

- WHY AMC BRIDGE?

- Deep knowledge and expertise in SOLIDWORKS and overall 3D printing domain knowledge

- Extensive experience with GPU development

- Proven track record of creating simulation applications for engineering, manufacturing, and construction on desktop, cloud, and mobile platforms

- Excellent development team profile to address business needs

- CUSTOMER BENEFITS

- The enhanced solution offered to end users as supplementary software for 3D printers designed and marketed by Desktop Metal

- Expanded and diversified Desktop Metal’s end user base

- Enhanced settings and simulation processing

Client

Desktop Metal (NYSE: DM), based in Burlington, Massachusetts, is pioneering a new generation of additive manufacturing technologies focused on producing end-use parts. The company designs and markets 3D printing solutions for all scales of production—from complex prototypes and on-demand tooling to the rapid manufacture of thousands of parts.

Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, Desktop Metal addresses unmet challenges of speed, cost, and quality to make metal 3D printing an essential tool for engineers and manufacturers worldwide.

Challenges

Advancing at a rapid pace, metal 3D printing has already overcome the geometric limitations of conventional manufacturing processes, creating new freedom for part shapes design. Nowadays, metal additive manufacturing technologies allow generating highly complex, lightweight, and stable structures that have never been possible with traditional manufacturing techniques, such as machining and casting. However, a lot of manufacturers and engineers are still challenged by the appropriate ways of using these technological advancements.

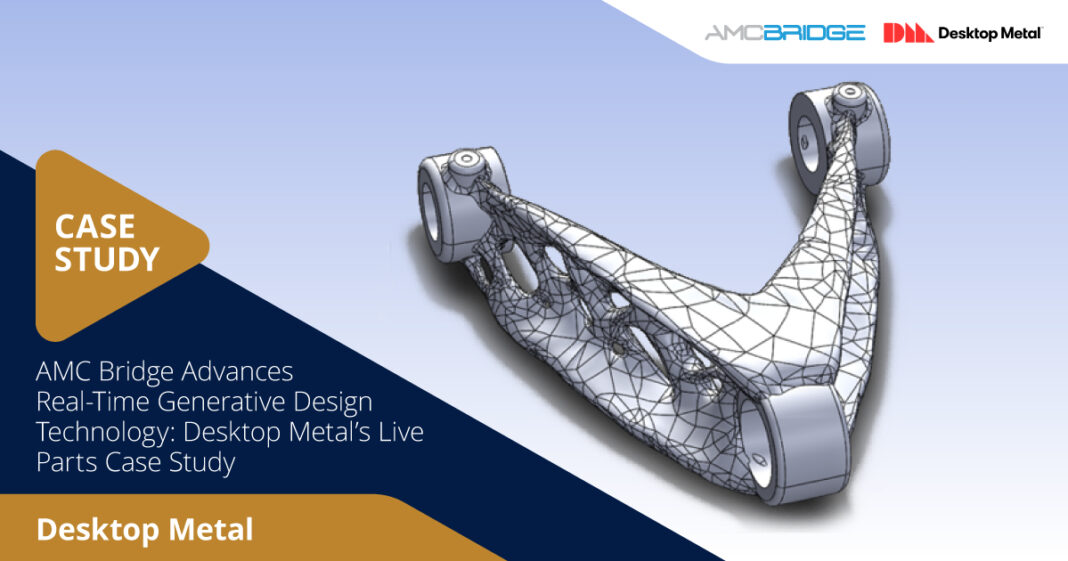

To demonstrate advantages of the latest innovations that enable creating light and strong designs similar to shapes found in nature, Desktop Metal had an idea of upgrading Live Parts, their existing technology, applying a growth-based approach, where parts grow similar to plants in the real world, that is, they become stronger in areas of high stress and strain. The growth algorithm was also aimed at improving the generative process by automatic handling of both design and manufacturing constraints. Besides, the client wanted to seamlessly integrate Live Parts into the CAD system environment.

With a proven track record of successful CAD interoperability developments, AMC Bridge was an ideal candidate for the project.

Solution

To fulfill the client’s needs, the AMC Bridge development team extended the functionality of the existing Live Parts technology and integrated it into SOLIDWORKS 3D CAD package.

Live Parts is a generative design tool that applies morphogenetic principles and advanced simulation to auto-generate part designs and generate new parts based on initial constraints specified by the user—restraints, loads, and so on. The tool produces geometry for lighter-weight, strong metal parts that can be efficiently printed.

The Live Parts functionality enables users to:

- Generate real-time parts from scratch using only initial constraints.

- Easily set constraints and loading conditions.

- Create optimized, manufacturing-ready models in a matter of minutes, mainly because of GPU-reduced design time.

- Control the modeling process.

- Directly export design changes to SOLIDWORKS and other CAD software for refinement, finite element analysis, and modeling.

- Easily adjust parameters in real time throughout the ‘growth’ process:

- Select material properties and create a particular material.

- Set up force magnitude and direction.

- Set up gravity direction.

- Tune up the safety factor, which affects the part’s thickness and robustness.

- Ensure integration between CAD software and Live Parts to receive fast optimization.

- Export files in the format needed for the manufacturing method selected by end users.

- Generate highly optimized parts that can stand up to strenuous conditions.

Aimed to ensure quick generation of optimized, manufacturing-ready models in a couple of minutes, Live Parts runs in the cloud on NVIDIA CUDA GPU–accelerated virtual machines.

Process

To achieve maximum efficiency during the development process, the AMC Bridge team of experienced professionals divided the scope of work into the following milestones:

- General functionality extension, development of the UI, core algorithms, and algorithms for growth control.

- Performance improvement using NVIDIA CUDA GPU:

- Face strain computations for voxels.

- Triangles snapping to initial mesh geometry.

- Full implementation of the SOLIDWORKS extension that allows creating input models for Live Parts.

- Development of the application update mechanism.

- Development of the web application to control Live Parts deployment on the Paperspace® cloud.

- Implementation of user subscriptions to different billing plans.

- Maintenance and further enhancements of the application.

The team worked in close collaboration with Desktop Metal to advance the technology and overcome the following key challenges:

- Adapting Live Parts to SOLIDWORKS entities and environment.

- Improving face strain calculation using NVIDIA CUDA to ensure better performance.

- Various user experience improvements.

- Changing mesh generalization.

- Integrating the finite element library for accurate model adjustment during the simulation process.

- Adding the versioning mechanism for input data to avoid conflicts between the new functionality and the previous data formats.

- Integrating the licensing library to make a standalone application.

Focused on progress at every project milestone, the team regularly provided deliverables of the developed functionality during weekly reports and meetings.

Upon completion of functional and regression testing, the ready-to-use technology was delivered to Desktop Metal.

Results

Due to the collaborative effort made by both teams during an iterative development, Live Parts was extended to a complex SaaS/PaaS solution. The resulting application is an industry-leading simulation software extension that fully meets users’ needs and requirements. It is used by innovative companies in various industries, from medicine, manufacturing, tooling, automotive, consumer electronics to oil and gas.

According to Design World®, a leading publication in the design engineering space, Live Parts was highly appreciated by the judging panel of LEAP Awards 2019 and became a gold winner in the Software nomination.

The efforts of the AMC Bridge development team were recognized by the client. In his feedback on working with the team, Andy Roberts, Technical Fellow at Desktop Metal, emphasized:

‘Continue to have a great experience working with the team. Highly communicative and appreciate the partnership!’

All third-party trademarks belong to their respective owners. For more details, please refer to the Third-Party Trademarks page.

Guest Post by AMC Bridge – https://www.amcbridge.com/case-studies/amc-bridge-advances-real-time-generative-design-technology-desktop-metal-s-live-parts-case-study